Table saw slide

I have a table saw with a crappy fence. It takes a long time and lots of measuring to set it correctly, and even then it isn’t as stable as it should be. I replaced it with a sliding table. This table is guaranteed to run exactly square to the blade, and allows for easy setting of cutting distances.

I have a table saw with a crappy fence. It takes a long time and lots of measuring to set it correctly, and even then it isn’t as stable as it should be. I replaced it with a sliding table. This table is guaranteed to run exactly square to the blade, and allows for easy setting of cutting distances.

This is the original table, with the crappy fence installed. The fence is only fixed to one side of the table, and is never entirely parallel to the blade. I always end up checking the distance to the front and the back of the blade with a rule, and then adjusting by hand. This just takes too much time.

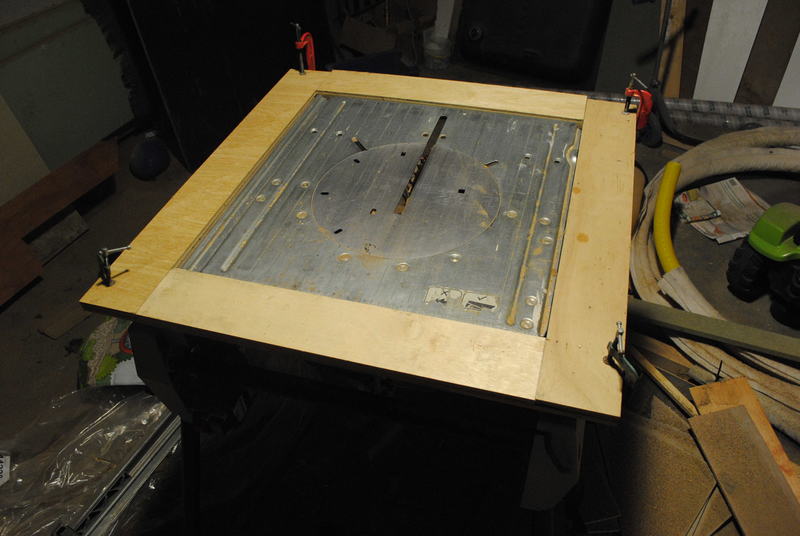

And this is the same table saw with the sliding table installed.

I started with constructing a sturdy frame around the existing table. It consists of 4 strips of 18mm multiplex which are glued together using a half lap splice joint.

The hinges of the table saw protrude into the frame so they were marked on the frame and routed out.

On top of the frame I laminated a large piece of 8mm multiplex. This forms the surface of the table, and the slide runs against its sides. Therefore it is important that this piece is precisely oriented to be square with the blade.

The runners were temporary used to position the outer sides of the slide for glueing.

The slide interface is wood on wood so it has quite a bit of friction. After applying silicon oil the friction is almost completely gone.

The sliding table has protruding runners glued to the underside, which slide into the top surface of the table.

With the sliding table it’s easy to make perfect square cuts. Just position the work piece against the fence and slide the table into the blade.